Researchers from UCLA have developed a SLA-based bioprinter that is able to create therapeutic biomaterials from multiple materials. This advancement could potentially be used for on-demand printing of complex artificial tissues for use in transplants and other surgeries.

Body tissues are highly complex and made of various different cell types, and this makes it a notoriously challenging thing to recreate in the laboratory. But advancements in bioprinting technology is helping to dissolve the difficulty that researchers have faced for years. The latest example of how 3D printing is changing the medical landscape comes from the University of California, Los Angeles.

A research team led by Ali Khademhosseini, a bioengineering professor at UCLA, has developed a new technique to 3D print more complex and therapeutic biomaterials from a range of ink-based materials. The development could signal a significant step towards enhancing on-demand access to bio-tissues for transplants and other surgical procedures.

“Tissues are wonderfully complex structures, so to engineer artificial versions of them that function properly, we have to recreate their complexity,” said Khademhosseini. “Our new approach offers a way to build complex biocompatible structures made from different materials.”

The research consists of using an adapted stereolithography (SLA) 3D printer to recreate the complexities of actual tissues in a body which often consist of multiple cell types. Khademhosseini’s team is reportedly the first to utilize multi-material SLA technology for such a bioprinting application.

New Stereolithography Bioprinting Technique Can Recreate Muscle-like Tissues

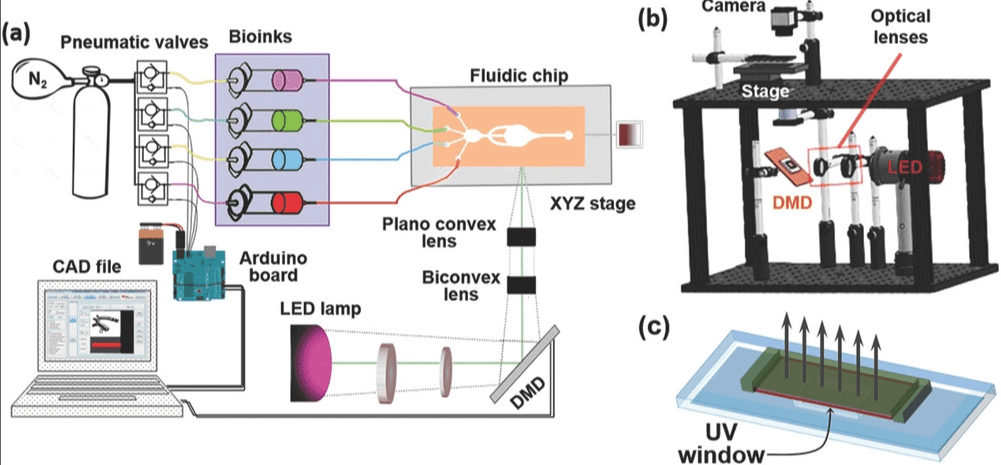

The modified 3D printer consists of a custom microfluidic chip with numerous inlets to print various materials. It also has a digital micromirror, which is an assembly of millions of small mirrors that can move independently.

To grow the tissues, his team is using various hydrogel-based materials. The micromirrors are being employed to manipulate the light that hits the surface with illuminated areas, indicating the outline of the soon-to-be-3D printed object.

This light source also activates the bonding of the molecular materials to ensure that a solid material is formed from the gel. With each step, the micromirrors change shape to direct light to the next area that will be printed. Although the researchers used four types of bio-inks in their demonstration device, they state that as many inks as necessary could be added.

At first, the research team used the process to produce simple shapes like pyramids. They eventually progressed to complex 3D structures that were able to mimic muscle tissues and muscle-skeleton connective tissues.

During testing, the team was also able to recreate muscle-like tissue as well as tumors and blood vessels, which could potentially be used as biological models to study cancer. Furthermore, they’ve already implanted these bioprinted structures into rodents to test their viability, and found that the tissues were not rejected by the hosts.

This development also highlights another important area for bioprinted tissues: research. Indeed, by being able to 3D print organs and even cancerous tissues on-demand, researchers will be able to enhance their findings and develop better medical solutions for those in need.

The final study, entitled “Microfluidics‐Enabled Multimaterial Maskless Stereolithographic Bioprinting”, was recently published in Advanced Materials.

Source: UCLA

Website: LINK