A team of Chinese plastic surgeons and tissue engineers have devised a method to 3D print cells which assemble into a replica of a patient’s ear.

Five children suffering from unilateral microtia in China are the first patients to receive newly grafted ears made from their own cells. Tissue engineers made the ears by combining cell culture methods with 3D printing.

Unilateral microtia is a deformity which results in deformed outer ears. Up until now, the only available treatment had been plastic surgery using a patient’s rib cartilage to form an ear shape. However, this relied on a surgeon’s expertise and skills to accurately shape the outer ear.

Thanks to 3D bioprinting, researchers have previously been able to create replicas of body parts and organs. Now, for the first time, researchers have grown ear-shaped cartilage in vitro (i.e. outside of a body).

The 3D Bioprinting Process in Detail

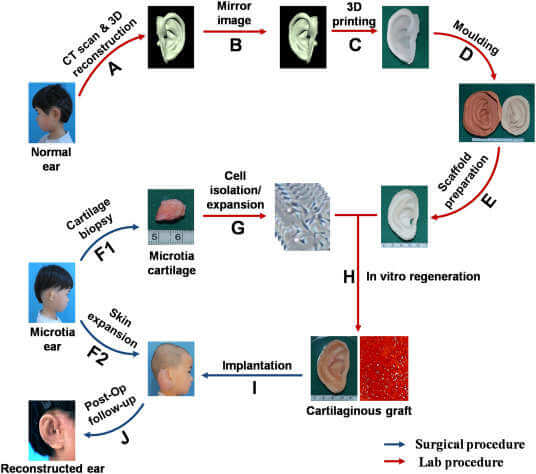

As described in a paper published by EBioMedicine, the team first took CT scans of the patients’ healthy ears. Subsequently, they created a mirror image of the ear using 3DPro CAD software.

The data was then used to create the 3D printed model which was cast as a mold using silicone and clay. The ear scaffold was cast with PGA, a biodegradable material and reinforced.

The team then isolated chondrocyte cells from the malformed ear tissue. Once the cells had grown to sufficient quantities, they were placed across the molds and incubated to nurture replication and growth.

It took 12 weeks for the cells to extend and form collagen and elastin fiber with the mold lattice.

At the same time, the PGA material degraded as the cells spread out. The finished implants consisted mostly of the children’s native tissues.

Following the surgery to place the ear, the patients were monitored over 2.5 years. Remarkably, the authors found that the chondrocytes remained healthy and intact. However, not all their trials went as planned. The authors admit that one of the patient’s new ear produced less cartilage, whilst another received a less aesthetically pleasing ear.

Despite these shortcomings, the new technique offers promise that it could be a viable method in future prosthetics.

Website: LINK