Our Chief Operating Officer and Hardware Lead James Adams talked to The MagPi Magazine about building Raspberry Pi’s first microcontroller platform.

On 21 January we launched the $4 Raspberry Pi Pico. As I write, we’ve taken orders for nearly a million units, and are working hard to ramp production of both the Pico board itself and the chip that powers it, the Raspberry Pi RP2040.

Microcontrollers are a huge yet largely unseen part of our modern lives. They are the hidden computers running most home appliances, gadgets, and toys. Pico and RP2040 were born of our desire to do for microcontrollers what we had done for computing with the larger Raspberry Pi boards. We wanted to create an innovative yet radically low-cost platform that was easy to use, powerful, yet flexible.

It became obvious that to stand out from the crowd of existing products in this space and to hit our cost and performance goals, we would need to build our own chip.

I and many of the Raspberry Pi engineering team have been involved in chip design in past lives, yet it took a long time to build a functional chip team from scratch. As well as requiring specialist skills, you need a lot of expensive tools and IP; and before you can buy these things, there is a lot of work required to evaluate and decide exactly which expensive goodies you’ll need. After a slow start, for the past couple of years we’ve had a small team working on it full-time, with many others pulled in to help as needed.

Low-cost and flexible

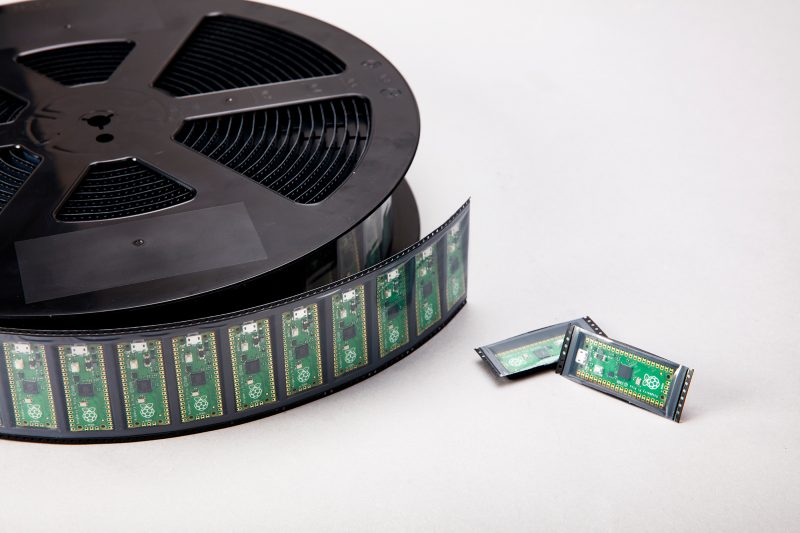

The Pico board was designed alongside RP2040 – in fact we designed the RP2040 pinout to work well on Pico, so we could use an inexpensive two-layer PCB, without compromising on the layout. A lot of thought has gone into making it as low-cost and flexible as possible – from the power circuitry to packaging the units on to Tape and Reel (which is cost-effective and has good packing density, reducing shipping costs).

“This ‘full stack’ design approach has allowed optimisation across the different parts”

With Pico we’ve hit the ‘pocket money’ price point, yet in RP2040 we’ve managed to pack in enough CPU performance and RAM to run more heavyweight applications such as MicroPython, and AI workloads like TinyML. We’ve also added genuinely new and innovative features such as the Programmable I/O (PIO), which can be programmed to ‘bit-bang’ almost any digital interface without using valuable CPU cycles. Finally, we have released a polished C/C++ SDK, comprehensive documentation and some very cool demos!

For me, this project has been particularly special as I began my career at a small chip-design startup. This was a chance to start from a clean sheet and design silicon the way we wanted to, and to talk about how and why we’ve done it, and how it works.

Pico is also our most vertically integrated product; meaning we control everything from the chip through to finished boards. This ‘full stack’ design approach has allowed optimisation across the different parts, creating a more cost-effective and coherent whole (it’s no wonder we’re not the only fruit company doing this).

And of course, it is designed here in Cambridge, birthplace of so many chip companies and computing pioneers. We’re very pleased to be continuing the Silicon Fen tradition.

Get The MagPi 103 now

You can grab the brand-new issue right now online from the Raspberry Pi Press store, or via our app on Android or iOS. You can also pick it up from supermarkets and newsagents, but make sure you do so safely while following all your local guidelines.

Finally, there’s also a free PDF you can download. Good luck during the #MonthOfMaking, folks! I’ll see y’all online.

Website: LINK