Raise3D has unveiled the Pro2 Series, a line of industrial-grade 3D printers that offer accuracy, reliability, and a wide range of material capabilities. The company has also announced a new vision to “Pathfind Flexible Manufacturing” by providing customized solutions for vertical markets.

Raise3D is aiming to become the “Pathfinder of Flexible Manufacturing” with the new Pro2 Series, the latest line of industrial-grade 3D printers to come from the Chinese manufacturer. The new 3D printer range, which includes the Pro2 and Pro2 Plus, offers dual-extrusion 3D printing, a wide variety of material compatibility, as well as accurate and reliable 3D printing performance.

On the surface, the Pro2 Series 3D printers look quite similar to the company’s N2 Series. However, Raise3D claims that the new product range serves a completely different market than previous machines.

“Even if our N2 printers have been considered among the best for desktop fabrication by Make Magazine and 3D Hubs Community, there was still room for improvement in some features. We carried out a full revision of our N2 series and designed a new printer with the best performance and quality components we could develop or find in the market. Our determination is to have the best possible FFF 3D printer to achieve our vision of Pathfinding for Flexible Manufacturing,” said Diogo Quental, CEO of Raise3D.

According to Raise3D, the Pro Series 3D printers will be one of the fastest in dual extrusion 3D printing. The company also states that printing accuracy is 16 times higher than the market standard, while both usability and reliability is greatly improved.

The pre-sale offer for Pro2 Series has officially started, and the official launch will take place on April 25 at the upcoming Rapid + TCT show in Texas.

Raise3D Releases the Pro2 and Pro2 Plus 3D Printers

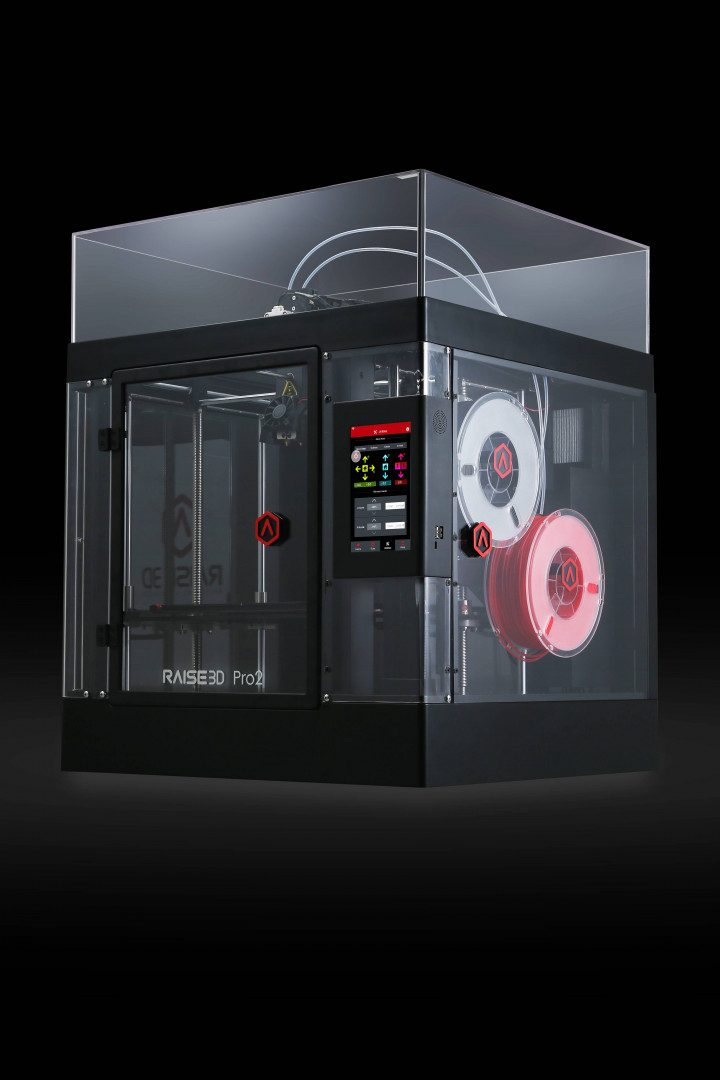

The company has just unveiled two new 3D printer models; the Pro2 and Pro2 Plus. Raise3D’s Pro2 is the smaller iteration of the duo, featuring a 305 x 305 x 300 mm build volume. This 3D printer also offers a layer height of 0.01 mm, a filament sensor, camera, and filter. Other benefits include the ability to resume printing after a power outage, wide material capabilities, and an intuitive user interface. This Pro2 is priced at $3,999.

Raise3D is also releasing the Pro2 Plus, which has a gargantuan build volume of 305 x 305 x 605 mm. Otherwise, this large-format 3D printer shares many of the same features as the smaller Pro2. The Pro2 Plus costs $5,999.

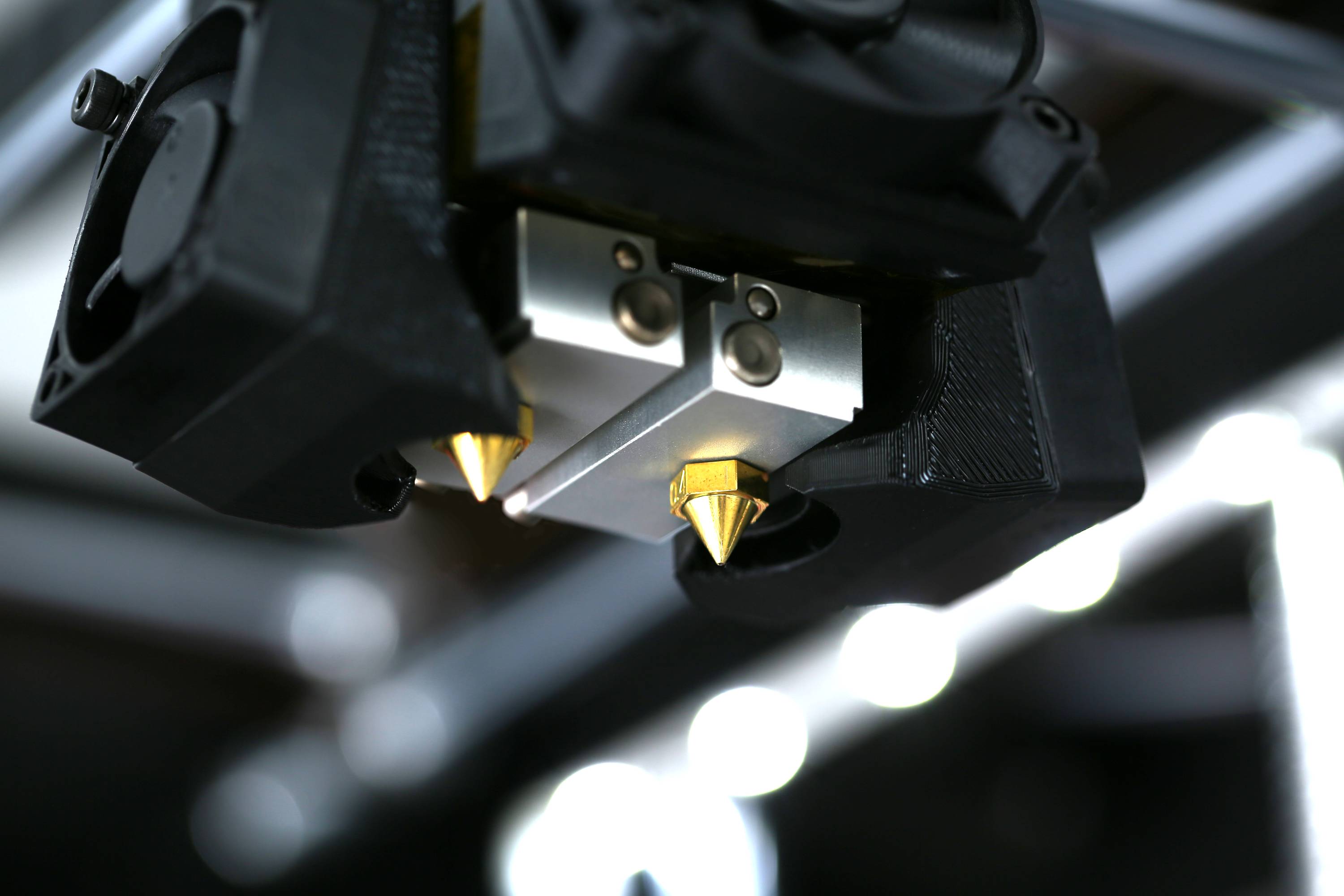

Both the Pro2 and Pro2 Plus has dual extrusion system that uses electronic driven lifting, which offers 4 times the increased torque performance. The Pro2 Series 3D printers also boast improved calibration, high quality optical endstops, an improved hotend and nozzle, and a new build plate system that prevents warping and distributes an even amount of heat.

Raise3D Launches New 3D Printers, Campaign to Become “Pathfinder of Flexible Manufacturing”

The range of new 3D printers is more than just an improvement over the N2 Series, but is also a major step towards the industrial market. With the Pro2 Series, Raise3D is striving to be the “Pathfinder of Flexible Manufacturing”. What does this mean exactly? Well, from what we can gather, Raise3D is looking to position itself in between mass production and the customization capabilities of additive manufacturing.

While mass production has improved lives in many facets, the industrialization has forced people to use the same exact products regardless of cultural differences. With 3D printing technology, Raise3D believes we are better able to create products that promote individualism and personalized experiences.

However, with the current inability to shine on the stage of mass production, additive manufacturing has been primarily reserved for prototyping or lower volume batches. To solve this problem, the Chinese 3D printer manufacturer has developed the Pro2 Series for use in Desktop FDM 3D printing factories, or as Raise3D calls it, Flexible Manufacturing.

“Flexible Manufacturing systems allow the creation of affordable (from 50K USD) manufacturing capacity, that can be efficient for batch sizes from 1 till a few thousands, easy to learn, easy to maintain, easy to upgrade and easy to scale-up,” the company states in its latest press release.

The Pro2 Series line will focus on offering high flexibility, especially in regards to materials and colors used, production of different materials, as well as parallel production of different batch sizes. Another benefit of utilizing this Flexible Manufacturing system is that it offers an affordable entry point for companies that are new to additive manufacturing.

At the moment, the details of the Pro2 and Pro2 Plus are sparse, but Raise3D will surely reveal further details and specifications in the near future.

Website: LINK