His solution was to make use of persistence of vision (POV) – the brief retention of a visual impression on the eye’s retina that creates the illusion of a moving image in film and television.

Shine a light

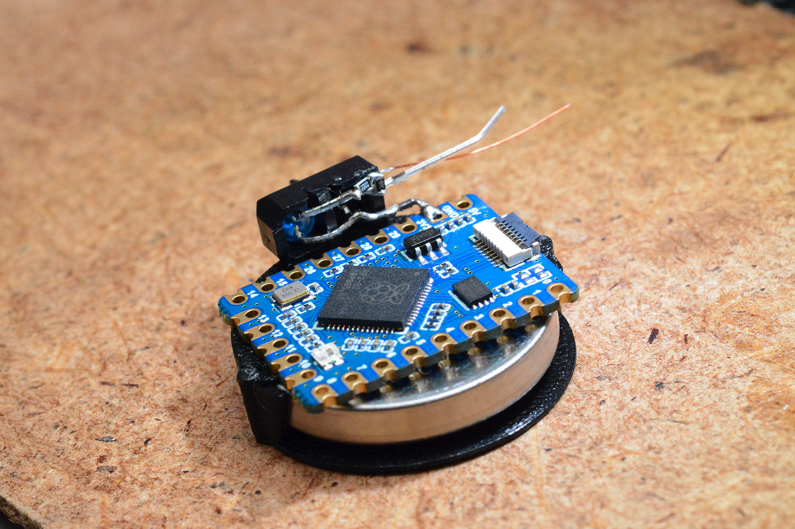

While the general consensus was that POV displays require too much in the way of supporting machinery to make them work, such as bearings and slip rings, Tim had the bright idea of getting a whole tiny device, including battery and motor, to spin.

He quickly threw together an LED matrix board design. “It took about a week for the matrix PCB to arrive,” he says, “which gave me a little time to think about how it was going to go together, but once I had all the parts building the whole thing only took a couple of hours.

For the brains of the device, he looked at using Raspberry Pi Pico, but eventually opted for a Waveshare RP2040-tiny partly due to its smaller size (about half that of Pico).

“Aside from the low cost and easy availability, one of the nice things about the RP2040 is that you can set, or get, all of the GPIO pins in a single clock cycle,” he notes. “This makes implementing a custom matrix very easy. The software [for the project] does very little at all: it just steps through an array of numbers to send to the GPIO port.”

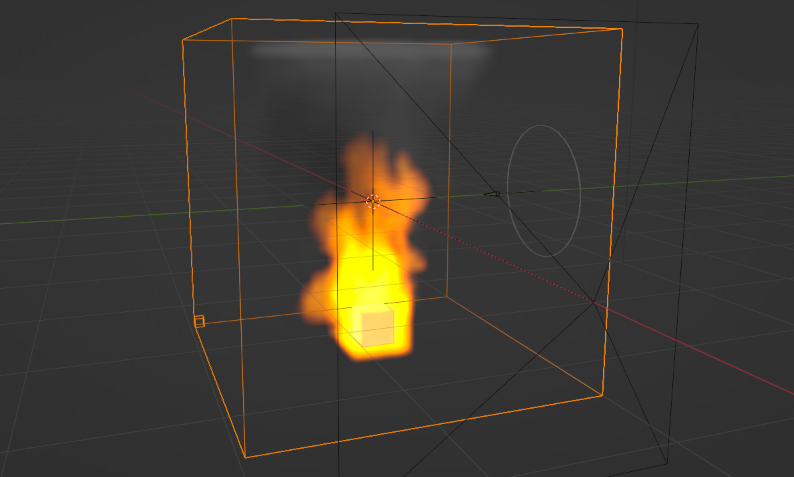

The flame effect is an animation based on volumetric data and rendered in the open-source Blender 3D modelling application. Tim first experimented with a rotating cube and fluid simulation. “Getting the software to work and generating those animations took maybe a couple of days of experimenting.”

Spinning around

The candle is spun around by a Mabuchi RF-410CA motor Tim had to hand. This can rotate at up to 5900rpm, but for a 30fps animation he used PWM to reduce it to around 1800rpm.

Power for the project is supplied by a LIR2450 coin cell housed in a custom 3D-printed battery holder. “The amount of current a battery can deliver is related to its capacity,” says Tim, “so it’s not just about making the battery last as long as possible, it’s also that a smaller battery might not be able to drive the motor at all.”

From this initial prototype, “the next step is to make a circuit board out of the hand-wired mess it is currently, and then increase the resolution of the display. We can roughly double the number of LEDs without changing the design, but beyond that we’ll need to rethink how the display is driven.”