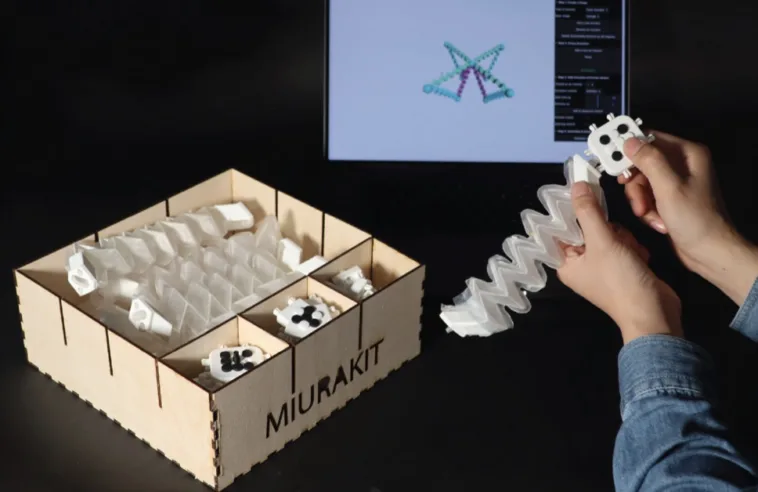

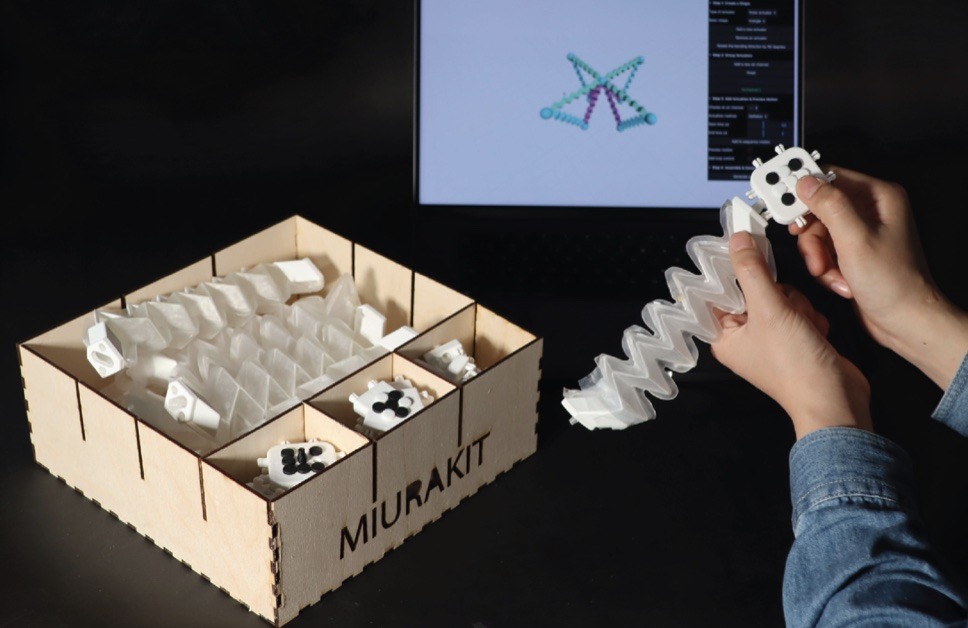

Soft robotics is a challenging field, because it comes with all of the difficulties associated with conventional robotics and adds in the complexity of designing non-rigid bodies. That isn’t a trivial thing, as most CAD software doesn’t have the ability to simulate the flexibility of the material. You also have to understand how the actuators will perform. That’s why a team of researchers from Zhejiang University and Carnegie Mellon University developed MiuraKit, which is a modular construction kit for pneumatic robots.

MiuraKit isn’t any one robot, but rather a set of tools and designs that can be combined to build robots and shape-changing interfaces. Anything made with MiuraKit will have a few things in common: pneumatic actuation, flexibility, and origami-like structures. Those structures expand or deform in a variety of different ways to suit the application. For example, one type is a simple one-dimensional expander similar to a linear actuator. Another type twists for rotary actuation. By linking different types together, roboticists can achieve complex motion.

Because these structures rely on pneumatic actuation, they need valves to control airflow. MiuraKit works with electromagnetic valves under the control of an Arduino board. That receives commands from a computer over a serial connection, but it can also work on its own with pre-programmed instructions. MiruaKit includes almost everything needed to create a robot: 3D-printable pneumatic connectors, a CAD design tool, laser cutter templates, and the pump with control system. In the coming weeks, the designers plan to give MiuraKit out to design firms and schools for evaluation.

Image credit: Cui et al.

The post MiuraKit simplifies pneumatic robot design appeared first on Arduino Blog.

Website: LINK