Additive manufacturing of metals grew rapidly between 2016 to 2017, driven by improved technologies and processing.

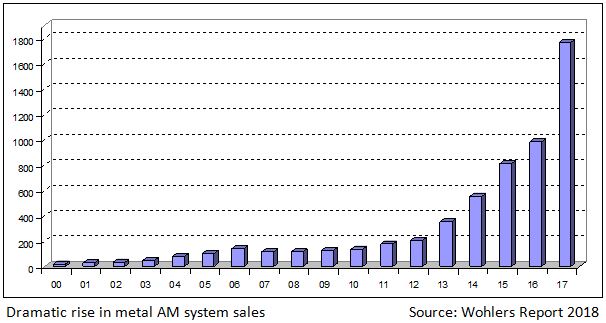

The sale of metal additive manufacturing systems increased by 80% in 2017 compared to 2016. Specifically, around 1,768 metal 3D print systems were sold in 2017 compared to 983 systems in 2016. These are the findings of the new annual report by Wohlers Associates Inc, the company offering strategic advice on additive manufacturing.

Among the factors driving the growth in metal 3D printing systems are improved process monitoring and better quality assurance procedures. The Wohlers Report 2018 also noted that manufacturers are becoming increasingly aware of the benefits of metal 3D printing.

Meanwhile, the number of companies now producing industrial-grade additive manufacturing systems – i.e. those that cost more than $5,000 – increased from 97 in 2016 to 135 companies in 2017.

It appears that new system manufacturers are joining the 3D printing market at a rapid pace. Furthermore, machines are now accompanied by improved material platforms, carry lower costs and provide faster printing speeds.

The final report comprises of the data findings from across 32 countries written by six co-authors.

Increase in metal 3D printing system sales over the years. (Image: Wohlers Associates)

From aerospace to medical industries – 3D printing of metals is on the rise

A similar report by IDTechEx estimates the worldwide market for metal 3D printing to grow to a $12 billion value by 2028.

Metal additive manufacturing to reach $12 billion in revenue by 2028. (Image: IDTechEx)

A wide variety of industries employ additive manufacturing of metals. These include aerospace engineering, automotive as well as the medical market.

Metals usually come in the form of powders and filaments for use in 3D printing. Currently, titanium and nickel are the dominant metals used in 3D printing systems, according to a report by Grand View Research. At the same time, steel is considered to be a cheaper alternative and given its wide availability may become a more dominantly used metal in the future for additive manufacturing.

The US currently leads in terms of market share with a CAGR of 30% in revenues. Meanwhile, Asia Pacific countries noted a significant growth of the metal 3D printing market.

Sources: Wohlers Associates, IDTechEx, Gran View Research

Website: LINK