The crash test dummy manufacturer Humanetics is using Markforged’s 3D printing technology and Onyx carbon-composite material to produce dummies the resemble elderly drivers, helping them accurately reflect injuries that could occur in a real car accident.

Car crash testing is an integral part of ensuring vehicle safety, and brave human-like dummies have been sacrificed to reflect the impact and injuries that actual drivers could sustain in an accident. However, until now, the selection of crash test dummies has been fairly limited in terms of resembling the gender and age of people. But that’s about to change as the crash test dummy manufacturer Humanetics has recently unveiled its first “elderly” crash dummy.

As the aging world population continues to grow driven by medical innovation and healthier lifestyle choices, many countries have noted an increase in older drivers. According to the US Census Bureau, there were more than 40 million licensed drivers over the age of 65 years in 2016. Given their fragile bones, elderly drivers are more likely to sustain bone and internal injuries when they crash.

Humanetics is using professional-grade 3D printing technology from Markforged in order to fulfill the often smaller quantity orders for specialist crash test dummies. Additive manufacturing offers a cost effective option to develop crash dummies that accurately reflect the elderly.

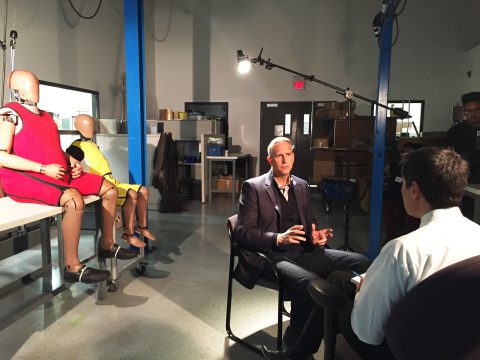

Mike Beebe, Chief Technical Officer at Humanetics, explained:

“It’s my job to look at the future. I’m always trying to figure out what new processes and materials we should develop going forward. One of the major discoveries we’ve made recently was that we could 3D print much of the elderly dummy. Now all of the components of the new elderly dummy, from the pelvis to the head assembly, are additively manufactured.”

Finding the right material and 3D printer

The team then set out to look for the right material to print the dummy. In initial testing the team found that rubber and plastic materials didn’t work well as the printed ribs began to crack after being tested just 20 times.

That’s when Humanetics decided to try out Markforged’s 3D printing technology and Onyx material. Onyx is a carbon-composite that is reinforced with Kevlar fibres, providing added stability, stiffness and high temperature tolerances. A test version using the carbon-composite withstood 60 to 70 impacts before visibly showing any damage. Even after 150 impacts, the Markforged 3D printed dummies remained intact.

Subsequently, Humanetics purchased a Markforged Mark Two 3D printer to print various parts of the dummies, including the ribs and skeleton. Although the cost of the carbon-composite material is close to the traditional steel used previously, a single rib can be printed in just 24 hours, ultimately reducing time and labor intensity.

In fact, the team at Humanetics has since found that additive manufacturing not only boosts their quality of their elderly crash dummies, but saves them 40-60% in assembly and labor costs. In the future, the company is planning to use 3D printing to produce and test internal organs. By developing products that accurately reflect the world’s population, car manufacturers will be able to use crash test results to build safer cars for everyone, young or old.

3D printed ribs by Humanetics. (Image: Humanetics)

Source: TCT Magazine/Humanetics

Website: LINK