CaloriSMART is an advanced model system that uses magnetocaloric materials to achieve refrigeration cooling. The system, that even could help you get a better fridge, was designed by researchers at the U.S. Department of Energy’s Ames Laboratory.

Gas compression refrigeration is a 100-year-old energy inefficient technology which needs updating. Researchers from the U.S. Department of Energy’s Ames Laboratory are working on new technologies to do just this.

Using 3D printing, they built an advanced model system that reaches refrigeration level cooling by using magnetocaloric materials. It was specifically designed to rapidly evaluate materials in regenerators and cut down manufacturing time and costs.

They call the contraption the CaloriSMART (short for Small Modular Advanced Research-scale) Test System. It could lead the way in developing energy-efficient cooling systems.

To test the system, they began by taking a sample of the chemical element gadolinium and subjecting it to sequential magnetic fields. The sample alternated between cooling down and heating up. Timed pumps circulated water during these cycles and the system delivered a cooling power of 10 watts. The gradient between hot and cold was 15 degree Celsius (just under 30° F). This process used just three cubic centimeters of gadolinium.

“Despite predictions, we would fail because of anticipated inefficiencies and losses, we always believed it would work… but we were pleasantly surprised by just how well it worked. It’s a remarkable system and it performs exceptionally well. Magnetic refrigeration near room temperature has been broadly researched for 20 years, but this is one of the best systems that has been developed,” said Vitalij Pecharsky who is CaloriCool project director and Ames Laboratory scientist as well as Anston Marston Distinguished Professor in the Iowa State University Department of Materials Science and Engineering.

Creating a 3D Printed Manifold for the CaloriSMART Test System

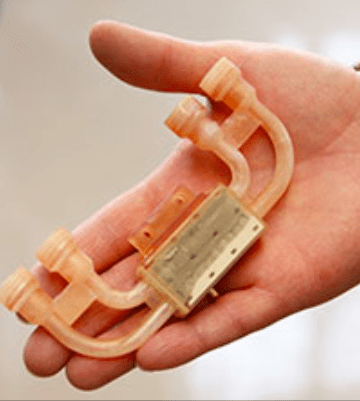

To create the system, project scientist Julie Slaughter and her team spent five months designing and building. They used 3D printing to create a manifold. This is the part of the system which holds the sample and circulates the fluid.

Therefore, this 3D printed part harnesses the cooling power of the system. By using 3D printing technology, the team was able to custom build the part to make sure it perfectly fit their needs.

As well as a 3D printed manifold, the system also has customized neodymium-iron-boron magnets. These magnets deliver a concentrated 1.4 Tesla magnetic field to both the pumping system and the sample.

“The main reason we conceived and built CaloriSMART is to accelerate design and development of caloric materials so they can be moved into the manufacturing space at least two to three times faster compared to the 20 or so years it typically takes today,” added Pecharsky.

The researchers have big plans for the future including upgrading the system to work with electrocaloric materials. Visit the Ames Laboratory and the Caloricool website to find out more – and let’s hope that your next fridge is more effective thanks to this technology.

Source: Press Release

Website: LINK

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.