Sounds like Sci-fi: Berkeley Scientists 3D printed entirely liquid materials that are flexible, stretchable, and could power electronics. They also could be used for chemical synthesis.

Researchers at the Department of Energy’s Lawrence Berkeley National Laboratory have figured out a way to print 3D structures that are made entirely of liquids. They used a modified version of the Qidi X-one low-cost 3D printer to inject water into silicone oil within a tube.

The researchers say the technique has potential applications for liquid electronics. Therefore, they could potentially power flexible and stretchable devices in the future.

Additionally, developers could use the tubes to separate molecules or deliver nanoparticles more effectively.

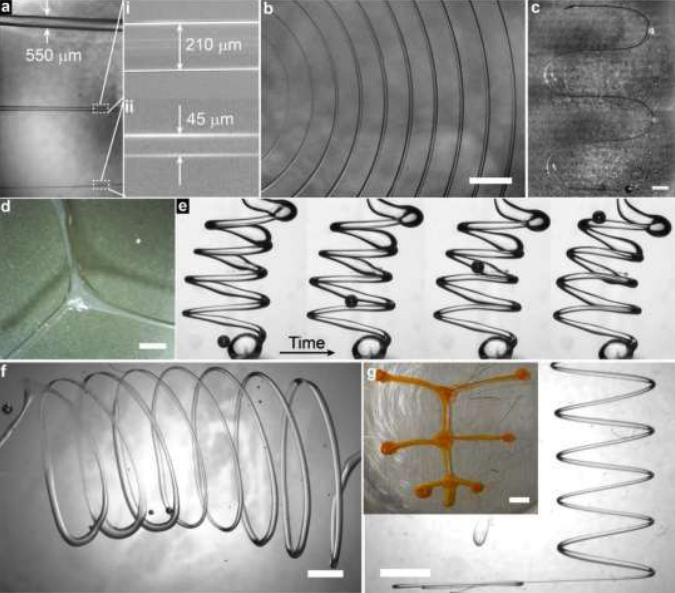

The 3D printed threads of water range between 10 microns to 1 mm in diameter. Tom Russell, a visiting faculty scientist in Berkeley Lab’s Materials Sciences Division, explained that the new materials essentially reconfigure themselves. As a result, it makes them suitable for many tasks “from chemical synthesis to ion transport to catalysis”.

Schematic of oil in water using supersoap. (Image: Berkeley Labs)

Developing the Material

The material essentially consists of a liquid tube inside another liquid. They achieved this by locking water into place using gold nanoparticles. These act as a surfactant which stabilizes the flow of the water and keeps the tube from breaking. Thus, the team dubbed the surfactant ‘supersoap’.

The supersoap also contains polymer ligands in oil. The polymer and gold particles attract each other, while the water and oil repel each other. This creates a powerful interface between oil and water that locks the two liquids in place.

“This stability means we can stretch water into a tube, and it remains a tube. Or we can shape water into an ellipsoid, and it remains an ellipsoid,” explained Russell. “We’ve used these nanoparticle supersoaps to print tubes of water that last for several months.”

The modified 3D printer

The researchers modified a Qidi X-one 3D printer by removing the parts that are traditionally designed to print plastic. Furthermore, they replaced them with a syringe pump and needle that extrudes liquid. Subsequently, the team reprogrammed the printer to inject oil and water.

“We can squeeze liquid from a needle, and place threads of water anywhere we want in three dimensions,” said Joe Forth, a postdoctoral researcher in the Materials Sciences Division. “We can also ping the material with an external force, which momentarily breaks the supersoap’s stability and changes the shape of the water threads. The structures are endlessly reconfigurable.”

The findings have been published in Advanced Materials. If you want to drill deeper, here’s the supplementary information.

Source: Berkeley Lab

The modified Qidi-X printer. (Image: Berkeley Labs)

Website: LINK

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.