By working with 3D printing technologies, Proterra has been able to save costs and speed up the production of its zero-emission battery-powered buses.

Proterra is looking to speed up its zero-emission bus mission by working with 3D printed parts. The Silicon Valley start-up focuses on solving public transport by developing electric buses that run without fossil fuels. The buses are also cheaper to maintain and operate.

In order to streamline production, Proterra has now partnered with Carbon, the 3D printing manufacturing company.

Manufacture of parts thus dropped 90-95%: The company was able to deploy its vehicles within just two weeks. Previously, it took three months to wait for the injection-molded parts to be ready.

Joshua Stewart, the Director of Customer Engineering at Proterra explained that using Carbon’s Digital Light Synthesis technology has overcome “the injection-molding tooling requirements when volumes are low”.

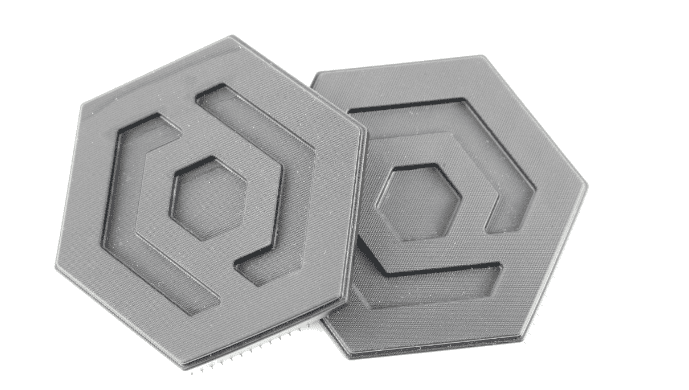

3D printed dash plate part. (Image: Carbon)

3D printing reduces costs and streamlines the process

At an average of four thousand different parts, each Proterra vehicle requires a series of different materials and manufacturing technologies. Additionally, orders for vehicles can vary depending on the customer.

A large number are injection-molded plastic parts. Costs for such parts range from $25,000 for small ones to $400,000 for large and complex ones.

If a customer makes a small order of five or 10 buses, injection-molding is more expensive. Instead, Carbon helps to overcome this problem by printing the parts using its M Series 3D printers and polyurethane material.

Another problem for the start-up was that its tool markers and material suppliers were separate entities. This can lead to lack of coordination and compromised part designs.

On the other hand, Carbon offers everything needed: the material, the 3D printers, and the software.

Trey Underwood, an engineer at Proterra added that final 3D printed parts “looked better than any injection-molded part I have previously seen for comparable dash plates.”

Lifetime cost savings of Proterra vehicle. (Image: Proterra)

Source: Carbon

Website: LINK

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.