Raise3D is striving to offer “Pathfinding for Flexible Manufacturing” through customized 3D printing solutions for vertical markets. To jumpstart the campaign, the new company has recently unveiled the Pro2 Series, a new series of desktop 3D printers made with industrial-grade components.

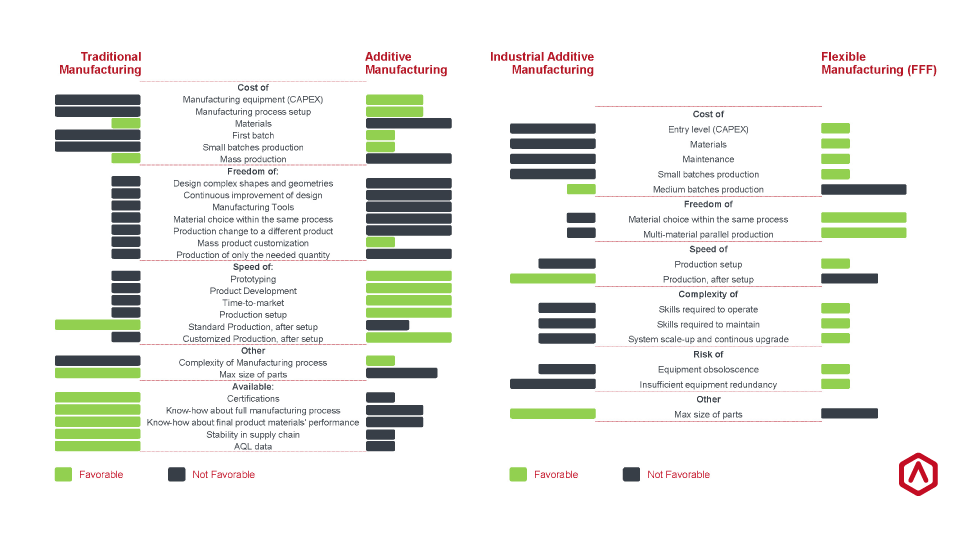

Additive manufacturing has unquestionably disrupted certain aspects of industrial manufacturing, particularly when it comes to production cost and speed. 3D printing technology does all of this while offering high potential for customization. It’s convenient for rapid prototyping and, in a growing number of cases, end-production too.

But there are still a number of barriers that have hindered the adoption of additive manufacturing in different industrial sectors. When it comes to high volume production with standardization, traditional manufacturing is still preferred over 3D printing.

Read more: Raise3D Aims to „Pathfind Flexible Manufacturing“ with Pro2 Series 3D Printers

What’s missing here is the transitional step between traditional manufacturing and additive manufacturing, and this is an issue that the 3D printer manufacturer Raise3D is currently aiming to tackle.

The company has launched a campaign to “Pathfind Flexible Manufacturing”. This industrial movement will be sparked by Raise3D’s Pro2 Series, a new series of 3D printers that are equipped with industrial-grade parts. But, in order to understand the company’s new focus, it’s important to grasp exactly what Flexible Manufacturing means and how it will change the way that additive manufacturing is utilized on the factory floor.

What is Flexible Manufacturing?

There are a number of factors that the bright minds within the additive manufacturing industry are working to solve, and Flexible Manufacturing could be the bridge that solidifies the connection between 3D printing technology and the industrial world.

The Flexible Manufacturing campaign from Raise3D focuses on building desktop FDM 3D printer factories with the new Pro2 Series 3D printer series. The company will offer customized 3D printing solutions to vertical markets, providing Flexible Manufacturing systems that are tailored for each customer and industrial sector.

This will enable the creation of affordable and specialized manufacturing capacity. With Flexible Manufacturing, customers can efficiently produce various batch sizes, ranging from one to a few thousands, and is also easy to learn, maintain, upgrade, and scale-up.

Raise3D’s latest range of 3D printers aim to break the boundaries that currently limit additive manufacturing, particularly in regard to materials and colors, parallel production of parts in different materials, as well as parallel production of different batch sizes.

On top of that, the Flexible Manufacturing program that Raise3D is developing also works as an entry level introduction to 3D printing technology.

How Raise3D Aims to Bridge the Gap Between Traditional Manufacturing and 3D Printing

After gaining recognition for the highly coveted N2 series, Raise3D is now producing the Pro2 series to serve professionals and businesses that want to integrate a Flexible Manufacturing system onto the factory floor. The Pro2 and the Pro2 Plus 3D printers are engineered for short-run manufacturing, and include dual extrusion, a sizable build volume, and other industrial-grade components.

From now until the end of the year, Raise3D will continue to prepare customized offers for various vertical markets. The company is open to talking with corporations interested in capitalizing on the opportunities that Flexible Manufacturing can potentially offer them.

In September, the company will offer the Raise3D Corporate Package Services, followed by the first customized 3D printing solutions for specific vertical markets at the end of 2018.

To learn more about or pre-order the new Pro2 Series, head over to Raise3D’s website.

Website: LINK