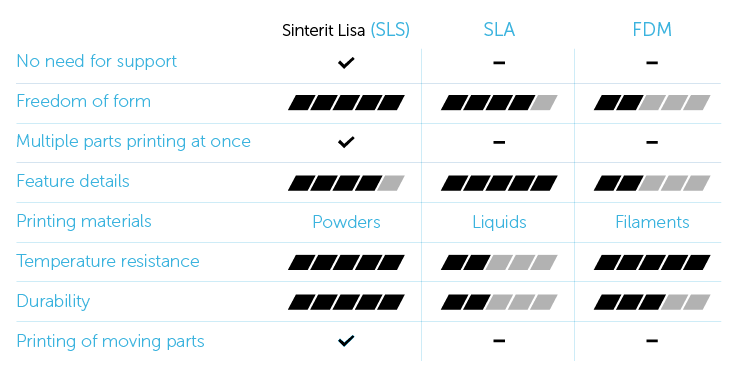

What makes the Sinterit Lisa so unique is the successful integration of SLS technology into a compact and easy to use machine. Generally speaking, there are a number of advantages that SLS technology offers over FDM and SLA, such as the ability to print without supports, nest multiple objects in a single printer, and produce parts that offer increased durability and temperature resistance.

The Sinterit Lisa manages to boast these same benefits at a major fraction of the cost. The printer is designed for small business, designers, or engineers that need functional prototypes and parts.

With SLS 3D printing technology, you are able to print without the need for support structures. Moreover, you can nest multiple parts in a single powder bed, making the technology more efficient than FDM and SLA 3D printing in many cases.

The Sinterit Lisa offers a minimum layer thickness of up to 0.075 mm, XY accuracy of .05 mm, and a 150 x 200 x 150 mm build volume.

The Sinterit Lisa also includes a 4-inch touchscreen to walk you through the entire printing process, from the initial set-up to cleaning the machine once the print is complete. There’s also Wi-Fi connectivity and an onboard camera, which means you can watch the print process through the screen.

Currently, Sinterit is offering two proprietary non-toxic powders, including PA12 and Flexa Black. After sandblasting the model, you’re left with a functional part straight from the printer. The Sinterit Lisa includes all of the tools you need to start printing, and the team also offers installation and training.

Although the Sinterit Lisa is compact and inexpensive for a SLS printer, it’s still a professional-grade machine that should be taken seriously. You need a workshop that is fit for handling tasks like sieving fine powder and sandblasting.

Nonetheless, the Sinterit Lisa is the most accessible SLS 3D printer currently on the market, making it a intriguing option for pro-sumers and small businesses.

Website: LINK