Iterate and improve

Designing the TouchCam gave Mukesh a chance to combine his skills as a maker and a computer science enthusiast. “My goal was to blend my love for creating things with my technical knowledge,” he enthuses of the versatile device “that can even work as a server for my test applications and database.”

Perhaps it’s no surprise that, as a computer engineer and developer, Mukesh works in a process of continuously improving successive designs. Mukesh says many of the design updates and improvements he made when moving on from the PiCam and developing TouchCam were directly influenced by the feedback he got from the design of the PiCam. It is also an apposite demonstration of how far his Fusion 360 computer-aided design skills have developed and was used to showcase his design prowess for his BSc.

With the TouchCam, Mukesh was keen to design a system that is compact and easy to carry and that would appeal to multitaskers who enjoy activities such as 3D printing, time-lapse photography, electronics, robotics, programming, and machine learning. He also thinks the TouchCam could be used for software development, low-cost personal servers, and similar uses.

Fine new features

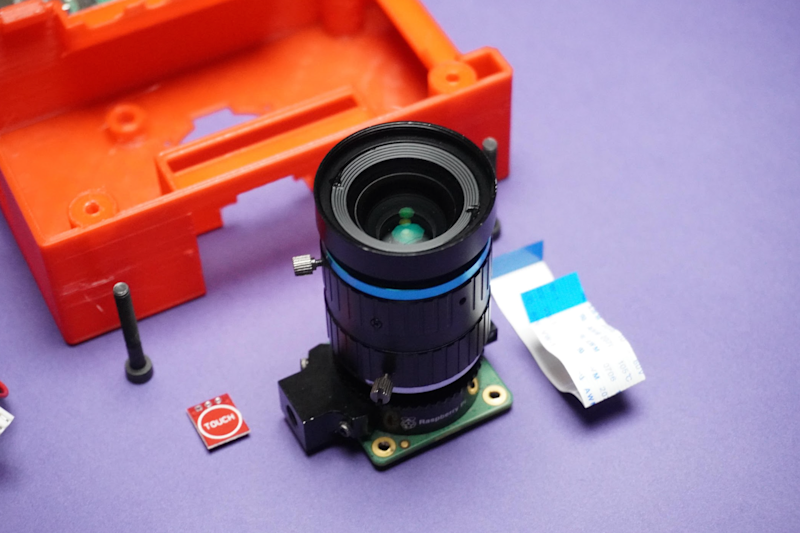

The TouchCam builds on the PiCam by integrating a high-definition touchscreen display and has a touch sensor that is used for live view, to access the photo gallery, and to switch between still, time-lapse, and video capture modes. The HQ Camera remote server also gained more prominence. “I chose the Raspberry Pi because it’s affordable, powerful, and has an internet full of resources. I am using the Raspberry Pi 4 8GB variant.” The components were sourced online, with standard items such as the HQ Camera paired with a DFRobot Raspberry Pi Touchscreen, cooling from a 5 V fan, and open-source software libraries such as Imager, and Silvan Melchior’s Raspberry Pi Camera Web Interface.

Having already got the basics down pat with the PiCam, the case design and touchscreen integration were the real challenges for this build. Only three 3D-printed versions were needed, and even these were simply to fix minor fit issues to accommodate the screws. Overall, Mukesh was pleased with the way the TouchCam turned out: “Everything from the outer shell that feels good to hold, to the special mounts that hold the camera perfectly. Each piece came from my careful design work, making sure they look good and work just right.”