There are a few approaches to making your own PCBs at home, and perhaps one of the most interesting yet potentially tedious methods involves making a UV-resistant mask and then etching away the non-copper areas with an acid bath. This etching step requires constantly moving the acid across the board’s surfaces for up to 30 minutes at a time, which is why Earl Daniel Villanueva made a small machine to handle this automatically.

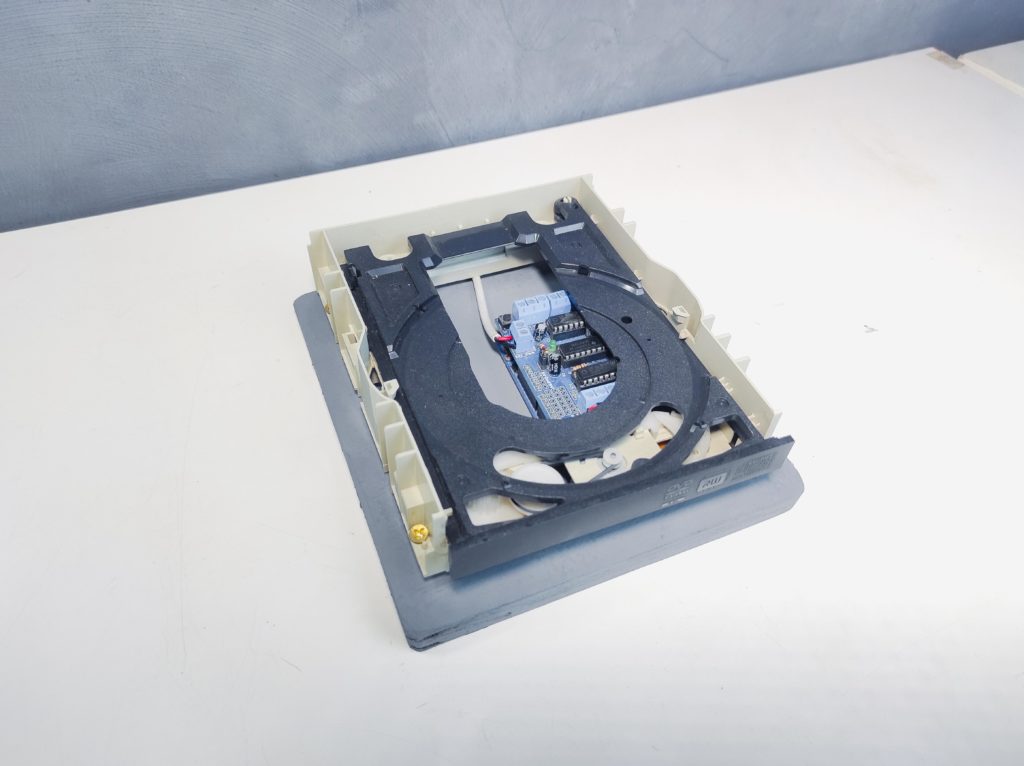

Villanueva began by gathering together an old CD-ROM drive, an Arduino Uno, an Adafruit Motor Shield, and a 5V power supply. The disc drive was chosen because it not only had an easily accessible DC motor, but also due to the disc ejection assembly being able to rapidly move in or out. After desoldering the motor from the drive’s mainboard and connecting it to the motor shield, he wrote a simple sketch for the Arduino that caused the motor to quickly oscillate between directions, thus creating the desired shaking motion.

Satisfied with the electronics, he then moved onto building a base plate from scrap wood and mounted the drive on top. Lastly, he attached a plastic container full of acid to the drive tray and watched as it continually swirled the solution across the PCB, resulting in a clean finished product.