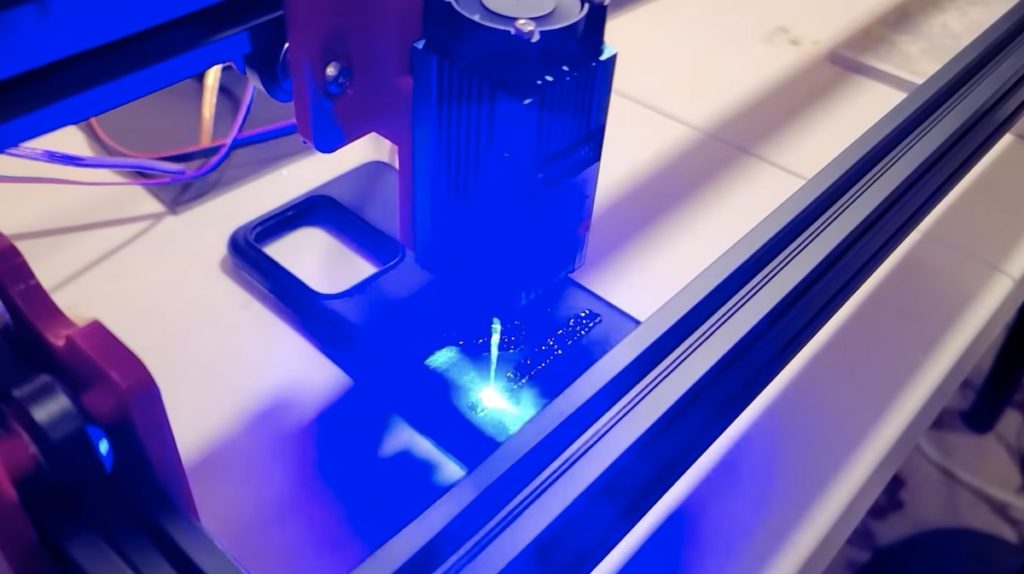

All makers love lasers and they make great shop tools. Even low-power lasers can engrave a variety of materials. Cutting material requires more power, with the most popular cutting lasers being CO2 with power between 10W-100W. But the small, affordable solid state laser modules can cut some materials, like acrylic, if you get a powerful enough model. If you want an affordable way to use one of those, then the Mokey Laser v1.0 is worth looking at.

Lasers like these can engrave and cut material, which means they can absolutely hurt you — your eyes are especially vulnerable. If you’re going to build something like this, make sure you understand how to operate it safely. It isn’t shown in the video, but you should absolutely use some kind of shielded enclosure that can handle the wavelength and power of the laser you use. Even with such an enclosure, you should wear the appropriate safety goggles.

This design cuts costs by utilizing 3D printer-style parts and by omitting the optics that are necessary for CO2 lasers. Because solid state laser modules are so compact, it is practical to move them on a gantry in the same way as a 3D-printer’s extruder instead of redirecting the laser beam with mirrors and lenses.

The structure of the Mokey Laser v1.0 is 8020 aluminum extrusion, which also acts as rails for the V-roller wheels on which the gantry rides. Most of the other parts are 3D-printed, with standard stepper motors and GT2 belts providing motion. An Arduino Uno board controls those stepper motors through a CNC Shield V3 with A4988 drivers. If you build this, you’ll have many software options. As shown, it runs GRBL 1.1 and that is compatible with almost every open source g-code sender out there, including some that are add-ons for Inkscape so you can control the laser from the same software you use to create toolpaths.

The total build cost with the bill-of-materials presented is $402.61, which makes this quite affordable for the size and capability.

One Comment