Researchers at the University of Buffalo have invented 3D printed dentures which can be used to deliver drugs among those highly susceptible to infection, such as the elderly, hospitalized or disabled patients.

For folks wearing dentures, an unfortunate side-effect can be fungal infections which cause inflammation, redness and swelling in the mouth. The condition is called denture-related stomatits, and according to some studies it impacts up to 70% of the denture-wearing population in the US.

To better treat these infections, researchers at the University at Buffalo have fabricated a set of 3D printed dentures filled with microscopic capsules that periodically release Amphotericin B, an antifungal medication.

In tests, the team found that the 3D printed dentures can reduce fungal growth. Unlike current treatment options — ranging from antiseptic mouthwashes, baking soda and microwave disinfection — the new development can also help prevent infection while they’re still in use.

“The major impact of this innovative 3D printing system is its potential impact on saving cost and time,” says Praveen Arany, DDS, PhD, the study’s senior author and an assistant professor in the Department of Oral Biology in the University of Buffalo School of Dental Medicine.

“The antifungal application could prove invaluable among those highly susceptible to infection, such as the elderly, hospitalized or disabled patients,” he continues.

Applications from this research could also be applied to other clinical therapies, including splints, stents, casts and prosthesis.

These 3D Printed Dentures Bite Back… at Infection

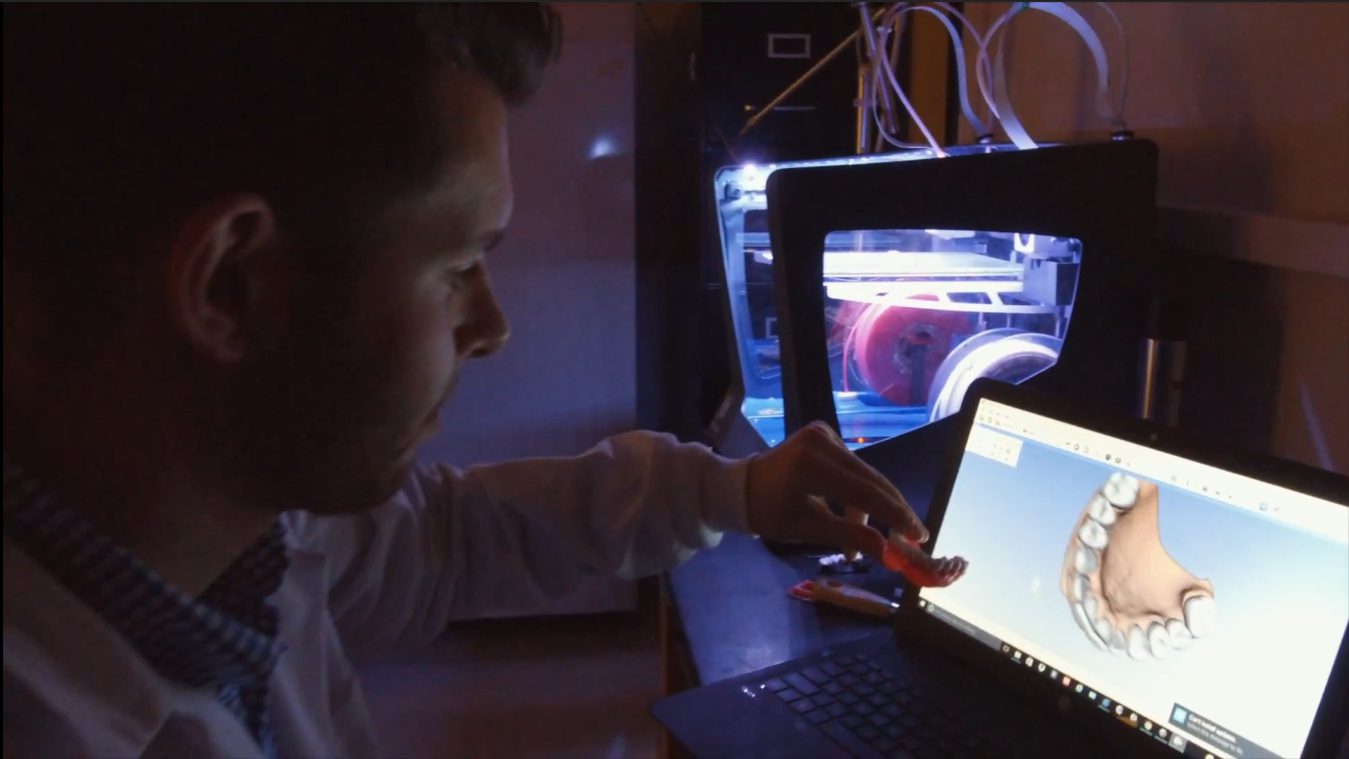

The researchers fabricated their dentures with acrylamide, the current go-to material for denture fabrication, on a BCN3D Sigma dual extruder 3D printer. The study sought to determine if these dentures maintained the strength of conventional dentures, and if the material could effectively release antifungal medication.

To test the strength of the teeth, researchers used a flexural strength testing machine to bend the dentures and discover their breaking points. A conventional lab-fabricated denture was used as a control. Although the flexural strength of the 3D printed dentures was 35 percent less than that of the conventional pair, the printed teeth did not fracture.

To examine the release of medication in the printed dentures, the team filled the antifungal agent into biodegradable, permeable microspheres. The microspheres protect the drug during the heat printing process, and allow the release of medication as they gradually degrade.

The dentures were tested with one, five and 10 layers of material to learn if additional layers would allow the dentures to hold more medication. The researchers found the sets with five and 10 layers were impermeable and were not effective at dispensing the medication. Release was not hindered in the more porous single layer, and fungal growth was successfully reduced.

Future research aims to reinforce the mechanical strength of 3D printed dentures with glass fibers and carbon nanotubes, and focus on denture relining. This is the term for the readjustment of dentures to maintain proper fit.

Would you like to learn more? A study describing the work has been published in Materials Today Communications.

Source: University of Buffalo

Website: LINK